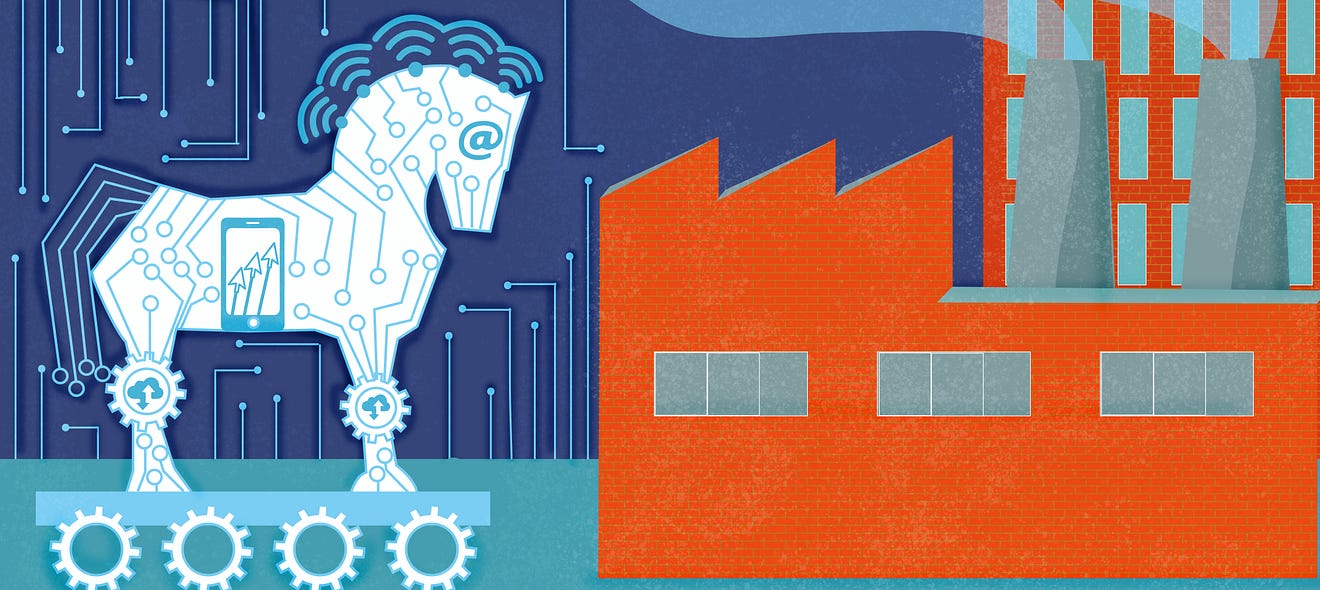

It’s well understood that we’re in the midst of a significant shift when it comes to industrial technology. The fourth industrial revolution has been enabled by various developments in key technologies such as cloud computing, machine learning, the Internet of Things, and others — all of which are set to disrupt the way that industrial organizations operate.

Those companies that are able to adjust to these new developments will be the ones that survive. What’s less well understood is why many companies still find it incredibly difficult to undertake this journey, despite the acknowledgment of the opportunities that it presents.

Rigid Processes

The very nature of an industrial operation is that you are focused on two main objectives: producing consistent high-quality and minimizing the risk of something going wrong. These are always at the forefront of your mind because of the high stakes of your operations and the costs of losing a client along the way. This mindset forces a rather rigid system because once you have something that works, it can appear irresponsible to experiment and take further risks. Thus, the status quo is entrenched in the company culture and the way that operational decisions are made.

This, of course, is not conducive to unlocking new product innovations that could transform the business. Using technology to augment an existing product and create a service offering from it represents an investment of time, energy, and resources that might not pay off. As a result, the company avoids it and continues doing what they’ve always done.

True digital transformation requires a willingness to experiment and go off the beaten path a little bit. Without that endeavor, your efforts are always going to be cut off at the knees.

“True digital transformation requires a willingness to experiment and go off the beaten path a little bit.”

If you’re attempting a digital transformation, and you haven’t revised your processes…what is it you think you’ve transformed?

Geared for Incremental Innovation

The word ‘transformation’ signifies a change that is not in lockstep with what has been done in the past. Companies that want to transition their business model and culture into the new paradigm must embrace this transformation and understand that it will reshape their organization entirely.

Unfortunately, industrial companies are, by their nature, geared only toward incremental innovation. Thus, they are very good at making an existing product 1 percent better than last month, but ask them to throw the blueprints away and start again — and you face a lot of resistance. However, this is the sort of first-principles thinking that is required.

A common example in industrial settings is when the servitization of existing product lines cannibalizes existing revenue streams because you’re putting more power in the hands of your customers. The Internet of Things specifically uses sensors and other monitoring capabilities to enable more self-service and this often scares industrial players. It appears to dilute their expert status and the reason that clients come to them in the first place.

However, those companies that push through the initial discomfort will realize that while existing products might be cannibalized, the transformation will create an entire spectrum of new opportunities for revenue generation. This way of thinking is exponential in nature, rather than incremental, and it’s one of the key stumbling blocks that we identified in our research. It’s not unique to industrial companies, but it is disproportionately present in these industries.

Company Culture

A cautious approach to digital transformation is one that will stumble along the way. This journey is not an easy one and industrial companies specifically face many obstacles as they seek to embed these emerging technologies into their offerings. What often differentiates those that succeed and those that don’t is the company culture that underlies the transformation. The attitude toward these shifts permeates through an entire organization from management all the way down.

It’s rare to see an industrial company that has nurtured a company culture that embraces change because of the high stakes involved in their work and the nature of the stakeholder relationships. But it’s a crucial piece of leveraging new technology to open up doors to new possibilities.

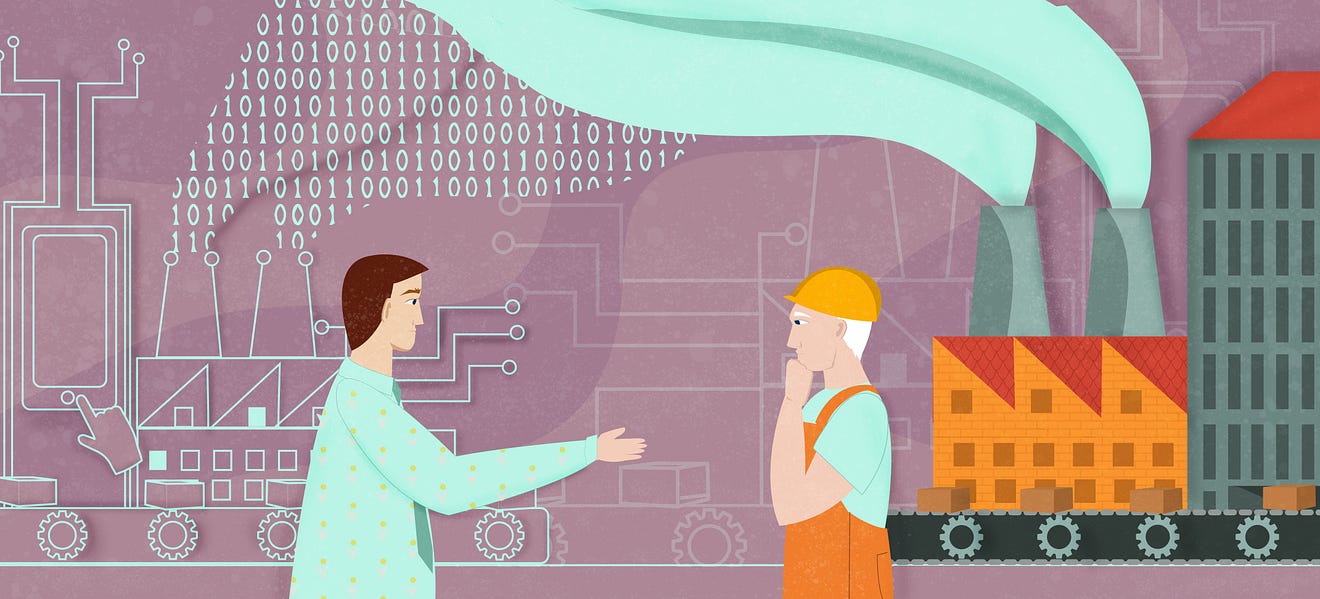

Social engineering is as important as the actual technology itself and often this is where companies get tripped up. It’s not enough to just slap a sensor on a piece of equipment and think that the smart capabilities are going to find product-market fit by themselves. It requires collaboration between functions, new messaging, tailored sales strategies, and more — all of which need to be driven by a desire to reshape the company from the ground up.

Conclusion

Shifting to this technologically-enabled future does not just happen on its own. Industrial companies need to build the right foundations in terms of operating models, business strategy, and revenue generation if they are to make the transition effectively.

New Episode

New Episode

Latest IoT News

Latest IoT News